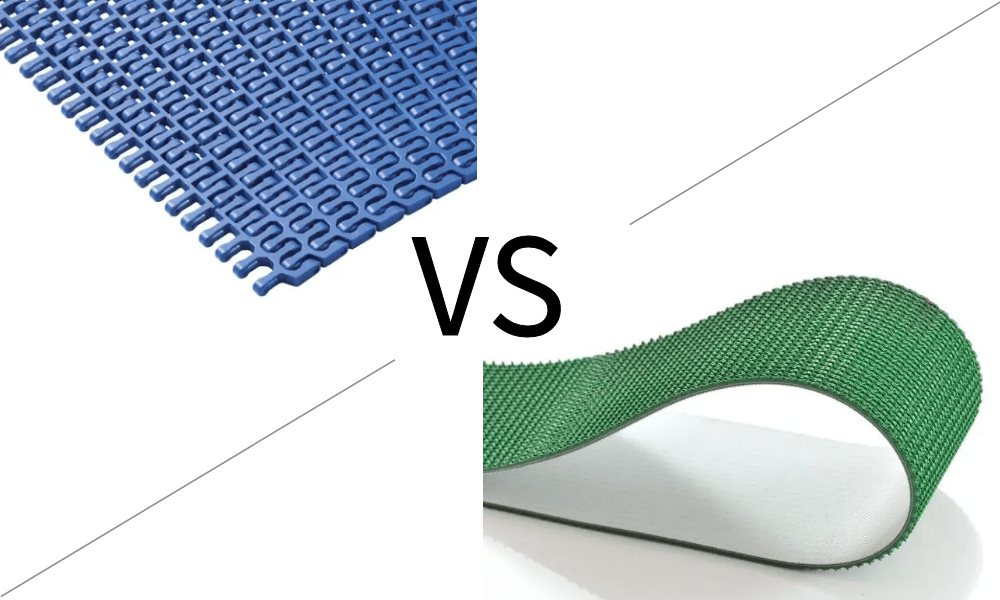

Conveyor Modular Belt Vs Conveyor Belt

Modular Belt Conveyors offer customers a safe, fast and easy way to transport their goods. Modular Belt Conveyor is a revolution to the traditional belt conveyor, it overcomes the disadvantages of belt conveyor which is difficult to maintain and prone to tearing, perforation and corrosion.

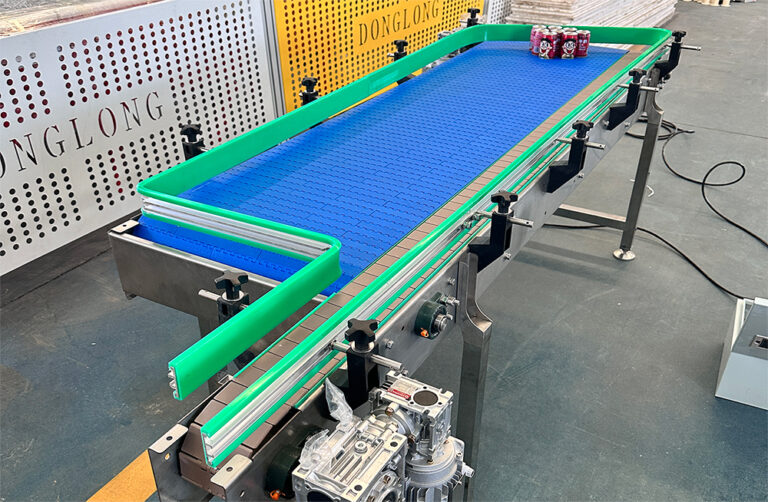

Modular belt conveyors use modular plastic belts and the conveyor drive is driven by sprockets, making it less prone to snaking and skewing.

The plastic chain plate of modular belt conveyor is very thick, which can withstand cutting, collision, oil and water resistance, etc. So modular belt conveyor won’t bring trouble to the maintenance of various industries when it is in use, especially when replacing the belt.

Modular belt conveyors are very stable and chemical resistant, and will not be damaged by detergents or high temperature hot water. Modular belt conveyors do not absorb any impurities from the surface of the belt. In this way, modular belt conveyors allow for the safest possible manufacturing process.

Modular belt conveyors are suitable for the transportation of small materials or special objects, such as magnetic materials. Modular belt conveyors also have a large conveying capacity and the length of the conveying distance can be adjusted. The length of heavy duty modular belt conveyor is generally not more than 15m, and the width is not more than 2m. the length of light duty stainless steel modular belt conveyor is generally less than 10m.

Modular belt conveyors are finished machines made of stainless steel. Therefore, the modular belt conveyor has a high strength body and good corrosion resistance, which can be used in high temperature corrosive environment. Moreover, some modular belt conveyors can also complete multiple process operations at the same time during transportation.

The above briefly introduces the advantageous features of modular belt conveyor, you can rest assured that the purchase, our company will be customized for you to provide solutions.