Features of plastic chain conveyor belt

Features of plastic chain conveyor belt

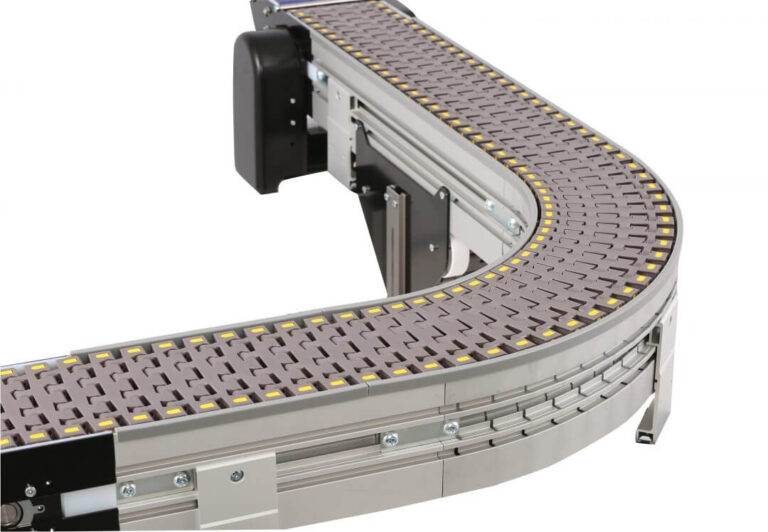

Plastic chain is a revolution of traditional belt conveyor. It overcomes the disadvantages of difficult maintenance of belt conveyor and easy tearing, puncture and corrosion of belt conveyor, providing customers with a safe, fast and simple maintenance conveying method.

Plastic chain is assembled by chain made of engineering plastic. Modular chain is interlocked or bricked and assembled by full-length pins. This design fundamentally improves the strength of conveyor belt. Baffles and side plates can also be interlocked with hinge pins to become one of the overall parts of conveyor belt. Plastic chain has various forms, flexible assembly and convenient replacement. Plastic chain is made of engineering plastic and connected with stainless steel pins. Compared with steel chain, it has the advantages of light weight and low noise.

Features of plastic chain: Modular plastic conveyor belt overcomes the pollution problem, uses plastic materials that meet hygiene standards and is integrally formed, and has no pores and gaps in the structure. No matter what product is conveyed: pork, chicken, duck, fish and shrimp, etc. It will not be penetrated by blood, grease and other pollution sources carried by the product. It will not absorb any impurities on the surface of the conveyor belt. In this way, the safest manufacturing process can be obtained. In addition, its stability and chemical resistance are particularly strong, and it will not be damaged by detergents or high-temperature hot water.

Plastic chain conveyor belts are easy to install, light in weight, low in noise, stable in operation, and self-lubricating, so they are widely used in conveying machinery and equipment in industries such as drinking water, beverages, beer, food packaging machinery, pharmaceuticals, canning, quick freezing, seafood, and vegetable cleaning as standard parts. Since this type of conveyor uses a modular plastic conveyor belt and the transmission method is driven by a sprocket, the conveyor belt is not easy to snake or deflect, and because the belt is thick and can withstand cutting, collision, and is oil-resistant and water-resistant, it does not cause trouble in maintenance when used by various industries, especially in replacing the conveyor belt.

As an important part of the conveyor, the choice of material for the plastic chain plate directly affects the performance and service life of the conveyor. The following are the commonly used plastics for plastic chain plates, which you can refer to.

1. Polyethylene (PE)

Polyethylene (PE for short) is a common material for plastic chain conveyors. It is durable, wear-resistant, and corrosion-resistant, and it is suitable for conveying materials with low temperatures. The surface of the polyethylene chain is smooth, not easy to adhere to materials, and easy to clean. At the same time, the PE material has certain flexibility and impact resistance, and can withstand certain impact loads. However, the temperature resistance of the polyethylene chain is low, and it will melt and deform when encountering high-temperature materials.

2. Polypropylene (PP)

Polypropylene (PP for short) is another common material for plastic chain conveyors. The polypropylene chain has good wear resistance and corrosion resistance, and is suitable for conveying some highly corrosive materials. Compared with the polyethylene chain, the polypropylene chain has higher temperature resistance and can withstand higher operating temperatures. In addition, the polypropylene chain has higher hardness and rigidity, and can work stably under larger loads. However, the polypropylene chain has poor impact resistance and is prone to breakage.

3. Polyoxymethylene (POM)

Polyoxymethylene (POM) is a high-hardness, high-strength plastic chain conveyor material. POM chain has good wear resistance, corrosion resistance and temperature resistance, and is suitable for some occasions with high material strength requirements. The surface of the polyoxymethylene chain is smooth and has good self-lubrication, which reduces the friction between the chain and the sprocket. However, the cost of POM chain is high, and it is relatively brittle, and it may break if it is subjected to excessive and frequent impact loads.

4. Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) is a commonly used plastic chain conveyor material. PVC chain has good corrosion resistance and wear resistance, and is suitable for some special working environments. It has high temperature resistance and can work at higher temperatures, but its temperature resistance is still limited compared to polypropylene chain. The surface of the PVC chain is smooth, easy to clean, and not easy to adhere to materials. However, PVC material becomes brittle at low temperatures and is prone to breakage, so low temperature environments should be avoided when using it.

5. Nylon (NYLON)

Nylon (NYLON) is a high-strength, wear-resistant engineering plastic, and is also one of the commonly used materials for plastic chain conveyors. Nylon chain plates have good toughness and wear resistance, and can withstand high impact loads. The surface of nylon chain plates is smooth, not easy to accumulate materials, and easy to clean. In addition, nylon material also has a certain temperature resistance and can adapt to higher operating temperatures. However, nylon chain plates are more expensive, relatively brittle compared to other materials, and cannot withstand excessive loads.

6. High-density polyethylene (HDPE)

High-density polyethylene (HDPE for short) is a plastic chain conveyor material with high density and rigidity. HDPE chain plates have high wear resistance, corrosion resistance and impact resistance, and are suitable for harsh working environments. It can withstand high loads and has good temperature resistance. At the same time, the surface of high-density polyethylene chain plates is smooth, not easy to accumulate materials, and easy to clean. However, the cost of HDPE chain plates is high and is not suitable for low-cost projects.

7. Polystyrene (PS)

Polystyrene (PS) is a plastic chain conveyor material with good insulation and impact resistance. PS chain has low density and light weight, and is suitable for some occasions with low load requirements. The surface of the polystyrene chain is smooth and not easy to adhere to materials. However, compared with other materials, the corrosion resistance of the polystyrene chain is poor, and it is not suitable for conveying some highly corrosive materials.