Product Advantages Of Plastic Modular Belts

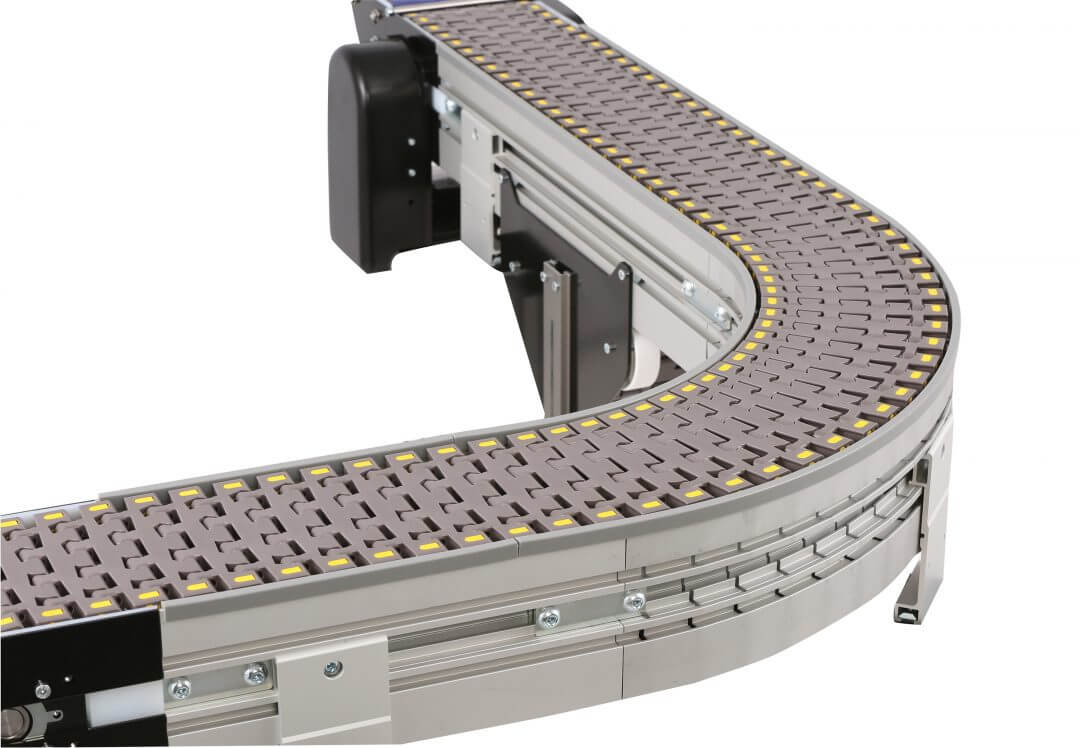

Plastic module mesh belt, also known as plastic module belt, plastic chain plate, module mesh belt, is composed of plastic modules and pins, and is driven by matching sprockets.

Compared with traditional conveyor belts, plastic module mesh belts have completely different structures and forms, so they have many unique characteristics:

Plastic module mesh belts do not slip during operation and are not prone to serpentine or deviation. This is because traditional conveyor belts are driven by roller sliding friction, while plastic module mesh belts are driven by sprocket meshing.

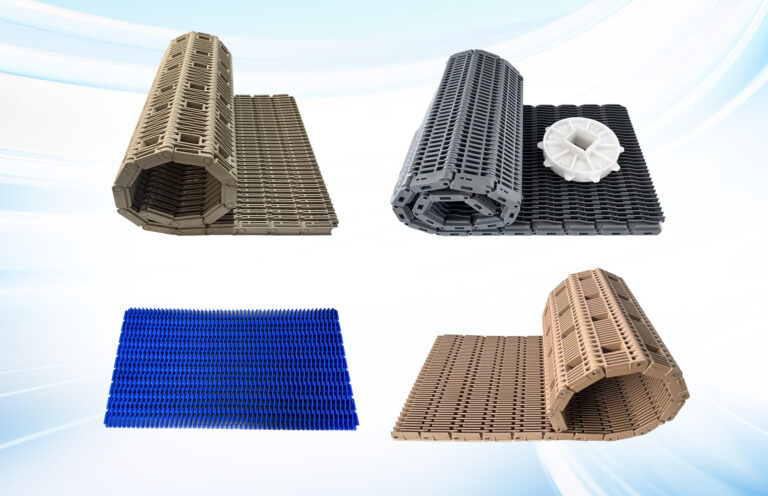

Plastic modules and pins are integrally formed, so they will not be penetrated by water, oil, etc., nor will they absorb impurities, overcoming the problem of easy product contamination.

Flexible and diverse product forms can meet the needs of various complex applications. For example, the open hole and flat grid types are suitable for breathable and watery occasions, and the ball type is suitable for automatic sorting applications.

A variety of materials are available, which are widely used in high temperature, low temperature, oil resistance, corrosion resistance, cutting and collision resistance, etc., and are widely used in food, beverage, chemical, rubber, tire, battery and other industries.

In addition to the above product features, the plastic module mesh belt also has unique advantages in convenient maintenance and replacement. The modular design allows the damaged part to be replaced without removing the entire conveyor belt, saving maintenance time and reducing inventory costs.