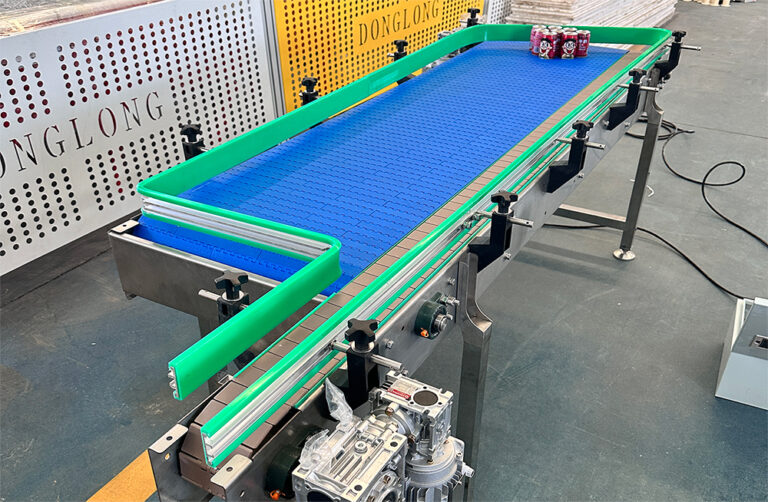

Flexible chain conveyor line

A flexible chain conveyor line is an automated conveying system that uses modular flexible chains as the core carrying and driving components, combined with a drive unit, support frame, guiding mechanism, and control system. It is also known as a flexible conveyor or plastic chain conveyor line. Its main advantage lies in ‘flexible layout and modular assembly,’ allowing free realization of multiple conveyance paths such as straight lines, curves, uphill/downhill, and lifting, without the need for complex transfer equipment. It can adapt to narrow spaces and irregular site layouts, making it a key piece of equipment for automated conveying of light to medium-weight materials. It is widely used in various industries, including food and beverage, pharmaceuticals and healthcare, electronics and electrical appliances, and e-commerce logistics.

Flexible layout, adaptable to complex scenarios

· Freely combine straight lines, 90°/180° turns, and slopes of up to 30° uphill or downhill. The minimum turning radius is only 1.5 times the chain width, requiring no special turning equipment. It can be flexibly deployed in narrow workshops and irregular spaces, maximizing space utilization.

· Modular splicing design allows conveyor length to be customized as needed. The line can be quickly expanded or its path adjusted later to accommodate dynamic production line upgrades (such as adding workstations or changing material flow).

Smooth transportation with low material damage rate

· The surface of the flexible chain plate is smooth, providing a large contact area with the material, running without jamming or bumping. Combined with a low-friction guiding mechanism, the material damage rate during transportation is almost zero.

· The plastic chain plate has slight elasticity, which can cushion the impact when placing materials. It is especially suitable for transporting fragile items (glass bottles, precision electronic components) and materials that are easily scratched on the surface (finished packaging, household appliance parts).

Operates quietly with low maintenance costs

· Plastic chain plates have a low friction coefficient with wear-resistant strips and drive sprockets, resulting in low operating noise, making them suitable for cleanrooms and electronic assembly areas sensitive to noise.

· Lubrication-free design: The plastic material has strong self-lubricating properties, requiring no regular addition of lubricating oil, thus reducing maintenance steps; worn chain plates can be replaced individually without disassembling the entire line, minimizing downtime for maintenance.

Highly efficient and energy-saving, with strong integration and compatibility

· Lightweight design: The overall weight is only 1/3 to 1/2 of a metal conveyor, reducing the load on the drive motor and suitable for long-term continuous operation.

· Seamless integration: Can be precisely connected with sorters, elevators, turners, workbenches, and other equipment, supporting multi-line merging/splitting, and adapting to the integration needs of automated production and sorting systems.

Application Scenario

Food and beverage industry: raw material transportation, filling line connection, packaging line conveying, cooling line transfer (such as beverage bottles, snack packaging, dairy boxes).

Pharmaceutical and medical industry: delivery of medicine bottles / reagent tubes, medical device assembly lines, material handling in cleanrooms.

Electronics industry: sorting electronic components, assembling mobile phone/computer accessories, small home appliance production lines.

- commerce logistics industry: sorting and connecting small express parcels, redirecting e-commerce packages for distribution, and warehouse inbound and outbound transportation.

Daily necessities/light industry: production line conveying and sorting of daily chemical products (shampoo, tissues), toys, and stationery.