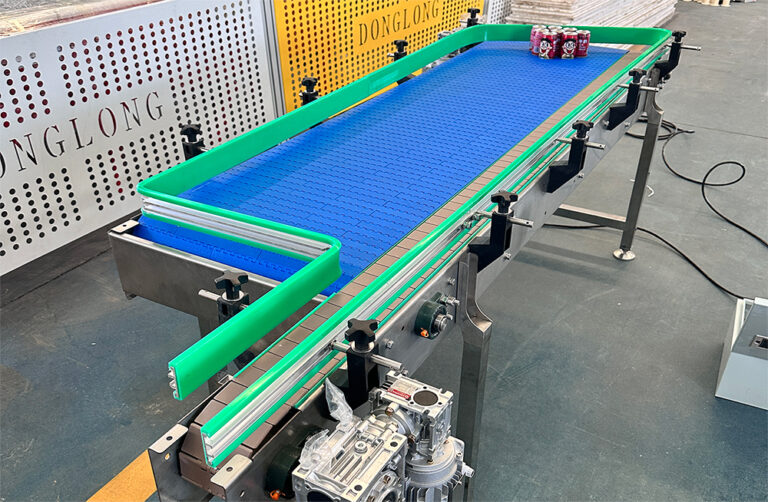

Modular turning conveyor equipment

Turn conveyor equipment is a core connecting device in automated production lines for industries such as food, pharmaceuticals, and electronics. It uses food-grade engineered plastic modular belts as the conveying medium, combined with magnetic guidance, variable frequency drive, and aluminum alloy frames, featuring three main advantages: small-radius turns, clean and quiet operation, and maintenance-free performance.

Main Advantages

Flexible steering and optimized layout: Supports 90°/180°/S-shaped turns, can seamlessly connect with straight conveyors, requires no manual handling, effectively avoids workshop columns, equipment, and other obstacles, reduces footprint by 30%-50% compared to traditional steering solutions, and is suitable for complex spatial layouts.

Supports multiple materials with a wide carrying range: can transport materials weighing 0.1kg-500kg, including cartons, pallets, components, fruits and vegetables, bulk materials, etc. Chain plate/roller models are suitable for heavy loads and unit items, while belt models are suitable for lightweight and fragile items, with a damage rate of ≤0.05%.

Smooth operation, low noise, and high efficiency: The transmission components engage precisely with the guide rails, ensuring that materials do not shift or tumble during turns, with low operating noise; the continuous conveying efficiency is 5-8 times higher than manual handling, making it suitable for large-scale production.

Wear-resistant and durable, easy to maintain: The core components are made of wear-resistant materials such as carbon steel and stainless steel, with a service life of 5-8 years under normal operating conditions; the modular design allows the transmission components to be individually disassembled and replaced, and routine maintenance only requires cleaning and checking tension.

Application Scenarios

Logistics and E-commerce: Turn conveyor/chain plate conveyors are used for directional sorting of cartons and packages, connecting with straight sorting lines to achieve automated linkage of ‘sorting – turning – warehousing.’

Food and Pharmaceutical Industry: Stainless steel turn chain plate/belt conveyors are suitable for food processing and bottle transportation, easy to clean and disinfect, compliant with FDA/GMP standards, with no sanitary dead corners at turns.

Industrial Manufacturing: Heavy-duty turn chain plate conveyors in automobile factories carry large components like engines and doors, enabling directional changes on assembly lines; turn belt conveyors in electronics factories transport circuit boards without scratches and with low noise.

Light Industry and Daily Chemicals: 180°turn conveyors enable folded production line layouts, save workshop space, and prevent bottled materials from falling with side guide rails.

Building Materials and Mining Industry: Used for turning block materials such as tiles and ores, wear-resistant and impact-resistant, suitable for both workshop and outdoor environments.