Application of plastic modules in the food industry

Plastic modules play an important role in various segments of the food industry due to their excellent hygiene characteristics, durability, and design flexibility. They can meet the applications and requirements in different scenarios:

Application field

Meat, Poultry, and Fish Processing:

Application Scenarios: Wet food and protein applications for red meat, poultry, and fish.

Tapered top and anti-slip belt design: Prevents product movement in wet and greasy environments while handling products gently to avoid damage.

Dynamic open hinge design: Facilitates thorough cleaning and reduces bacterial hiding spots.

Metal X-ray detectable materials: Enhance food safety and make it easier to detect contaminants.

Baking and Confectionery Production:

Application Scenarios: Conveying, fermenting, cooling, and freezing products such as bread, biscuits, and candy.

Micro-Pitch Series: Enables compact conveying (minimum pitch as small as 8mm) with smooth transitions.

Spiral Conveyor Belt: Saves space with high airflow circulation, suitable for fermenting, cooling, and freezing.

Diamond Top Mesh Belt: Prevents raw dough from sticking and reduces flour usage.

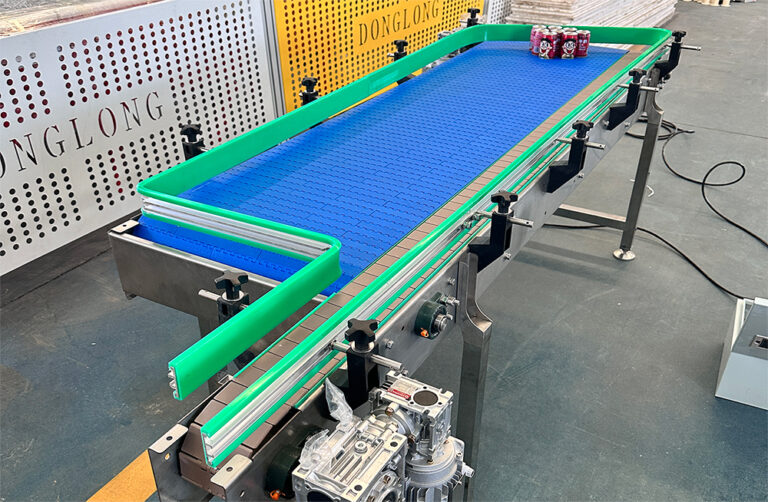

Fruit and Vegetable Processing and Beverages

Application Scenarios: Fruit and vegetable processing, beverage manufacturing, canning industry, etc.

Hole Design: Facilitates cleaning, draining, and cooling.

Flat-Top Chain: Suitable for conveying PET bottles, cans, cartons, pallets, and other packaging containers.

Other food processing: frozen food production lines, aquatic product processing lines, etc. Features include high and low temperature resistance (-70°C to 240°C) and corrosion resistance (able to withstand cleaning agents).

Key Points and Precautions for Model Selection

When choosing a plastic modular belt, several key factors need to be considered comprehensively to ensure production efficiency and food safety:

· Choose according to the type of food:

· When handling moist, fatty meat, poultry, or fish products, belts with non-slip surfaces (such as conical top designs) and open hinge structures should be prioritized, as they help prevent product displacement and facilitate thorough cleaning.

· For sticky dough or certain candies, conveyor belts with diamond patterns or special textured surfaces can effectively prevent sticking.

· For processes such as washing fruits and vegetables, belts with a high open area should be selected to allow for draining and cleaning.

Consider the processing environment:

· The modular belt needs to adapt to a wide temperature range, such as spiral freezing, cooling (low temperature), or high-temperature sterilization processes.

· It must be able to withstand repeated washing and disinfection with corrosive cleaning agents commonly used in the food industry.

Focus on hygienic and safe design:

· Choose products with designs like dynamic open hinges, which can avoid sanitary dead spots and allow cleaning agents and water to reach all surfaces, adhering to the golden rules of food hygiene.

· In high-risk areas such as meat processing, prioritize selecting modular belts made of metal or detectable by X-ray. In case of accidental damage, even tiny fragments can be detected by inspection equipment to prevent contaminants from mixing into the product.

Ensure compliance and standards:

· The chosen module strips must be made of food-grade safe materials and comply with the regulations on food contact materials in the target market.

Plastic modular belts have become an indispensable part of the modern food industry due to their excellent hygiene, outstanding durability, flexible custom design, and convenient maintenance features. Proper selection and application of these conveyor belts can not only improve production efficiency but also ensure food safety and protect the company’s brand reputation. Donglong Transmission has fifteen years of experience in designing, producing, and selling modular conveyor belts, allowing us to professionally help you choose the right product and provide optimized selection and product solutions. Our products meet international certifications such as the U.S. FDA and European CE. For any needs or challenges related to modular conveyor belts, please feel free to contact our sales engineers.