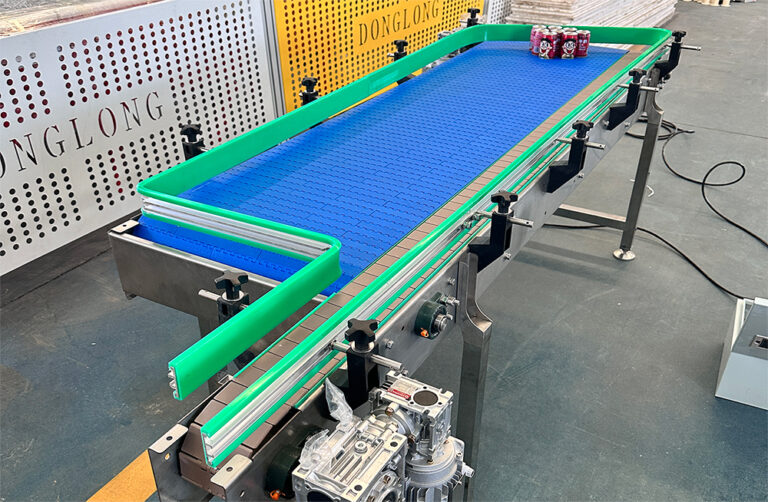

Ball Bearing Conveyor Sorting and Side Alignment Equipment

The ball mesh conveyor sorting and side-alignment equipment is a flexible sorting and guiding device used in logistics sorting and production conveyor lines. It uses a ball mesh conveyor as the core transport medium. Through freely rotatable balls embedded on the surface of the mesh belt, combined with side guidance mechanisms, it enables smooth diversion, precise side alignment, or directional sorting of goods. It meets the automated handling needs for light to medium-weight materials in the e-commerce logistics industry and serves as a key supporting device connecting production lines with sorting systems.

Core Advantage:

Flexible sorting, compatible with various types of materials: The ball rollers can rotate freely 360°, and with adjustable guide baffles, they can achieve multiple actions such as 90°turns, oblique diversion, and precise side alignment of goods. They are compatible with regular and irregular materials such as cartons, turnover boxes, bagged items, and flat items, and the sorting categories can be switched without replacing core components, making them highly adaptable.

Smooth conveying with low cargo damage rate: The contact area between the ball bearings and the cargo is small, and the friction coefficient is extremely low. During transportation, there is no dragging or scratching of the cargo, making it especially suitable for fragile items, precision electronic components, and well-packaged finished products that require high protection. The sorting damage rate is nearly zero.

Compact structure and high space utilization: The equipment features a simple overall design without the need for complex transmission mechanisms. It can be directly integrated into existing conveyor lines, has a small turning radius, and can be flexibly deployed in narrow workshops or compact sorting layouts, effectively saving floor space and meeting the requirements of three-dimensional logistics layouts.

Efficient operation with lower energy consumption: Using lightweight ball mesh belts and a low-power drive system, it operates quietly and consumes only 30%-50% of the energy of traditional sorting equipment; it meets medium to high-frequency sorting needs, with fast start and stop response and no inertial lag.

Easy maintenance and long service life: The ball mesh belt is made of food-grade PP/POM materials, which are wear-resistant, corrosion-resistant, and aging-resistant, and do not require regular lubrication. Its modular design makes belt replacement and ball inspection more convenient, with core components having a long service life and low maintenance costs.

Core role:

Precision sorting and routing: In logistics sorting centers and e-commerce warehouses, goods can be directed to designated slots, conveyor lines, or sorting stations based on their destination, category, and order information through guiding mechanisms. This replaces manual sorting and improves sorting accuracy and efficiency.

Cargo edge alignment: In scenarios such as production line transfers and packaging line preprocessing, loose goods on the conveyor can be quickly guided to one side and precisely aligned, facilitating the automated connection of subsequent processes like barcode scanning, weighing, and packing, and preventing process interruptions caused by cargo misalignment.

Assisted automation integration: Can seamlessly connect with WMS, PLC control systems, barcode scanners, and photoelectric sensors to achieve automatic assignment of sorting tasks, goods arrival detection, anomaly alerts, and other functions. It supports unattended operations, helping to build an automated and intelligent production logistics system.

Protect materials and equipment: Reduce wear on material packaging through low-friction conveying and avoid collision damage caused by manual handling; at the same time, isolate direct contact between materials and equipment frames, reduce line wear, and extend the overall service life of the conveyor system.

Welcome to contact us to learn more about our products and get a free technical solution! Shandong Donglong Transmission Equipment Co., Ltd. looks forward to working with you to create brilliance together!