What is a convex ribbed modular belt?

What is a convex ribbed modular belt?

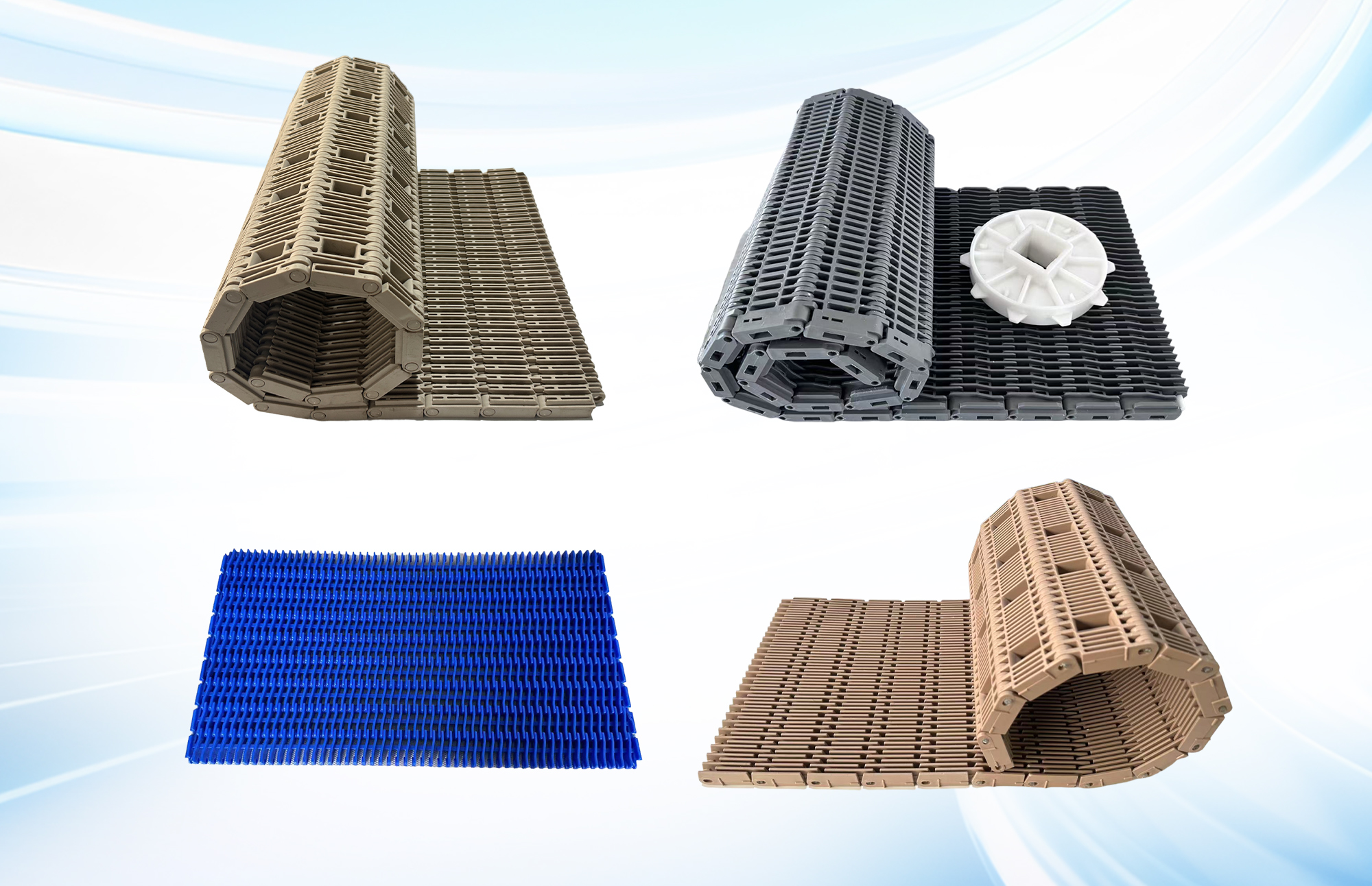

A ribbed modular belt is a special type of plastic modular conveyor belt. The main difference between it and a regular flat modular belt is that its top surface is designed with raised ribs. These ribs are usually evenly spaced and arranged perpendicular to the direction of the belt’s movement or at a certain angle.

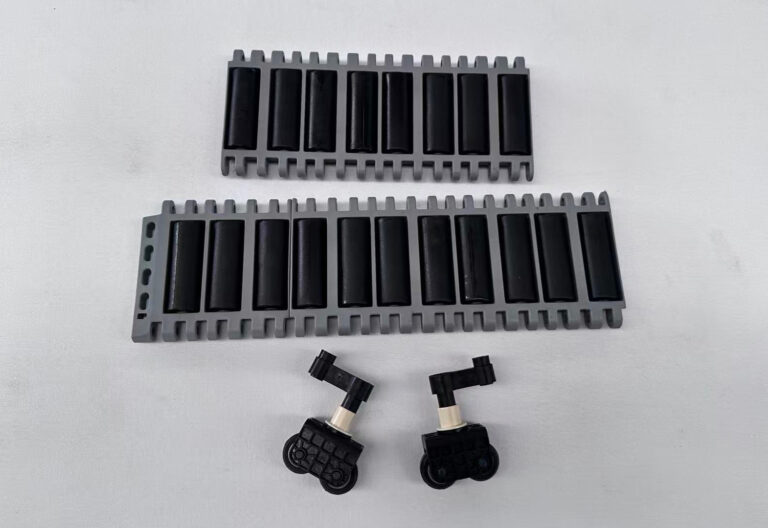

The basic structure consists of individual modules made by injection molding high-strength engineering plastics (such as polypropylene PP, polyethylene PE, and polyoxymethylene POM), which are assembled into a complete, flexible conveyor belt through hinged connections.

Main Application Scenarios

The design features of the ribbed modular belt make it particularly suitable for applications that require anti-slip properties, stable transmission, drainage, conveying, or positioning. The main industries of application include:

- Food processing industry (most widely used)

· Bottled Beverage Line: The ribs can perfectly separate and stabilize PET bottles, glass bottles, and cans, preventing them from tipping over on horizontal or inclined sections. On ascending sections, the ribs provide reliable support for the containers, preventing them from sliding down.

· Canned food line: conveys metal cans and glass jars (such as for jam or canned goods), serving the same purpose as above.

· Frozen foods (such as frozen dumplings and tangyuan): the gaps between the raised ridges allow cold air to circulate, improving freezing efficiency. They also make draining easier (after thawing or washing).

2. Non-food Industry

· Cosmetics industry: transporting packaging containers such as perfume bottles and skincare jars, requiring smooth handling without scratches.

· Electronics manufacturing: Conveying small electronic components or packaging boxes, can also be customized to meet anti-static requirements.

· Auto parts: Transport small components for assembly or packaging.

Main Advantages

The ribbed module belt combines the general advantages of plastic modular belts with its unique structural benefits:

1. Excellent slip resistance and stability

· Key Advantage: The raised ribs create a physical barrier, greatly increasing the friction between the product and the conveyor surface, effectively preventing the product from sliding, rolling, or tipping during transportation, especially during acceleration, deceleration, inclines, or climbs. This is crucial for containers with smooth bottle bodies.

2. Excellent drainage, quick-drying, and breathability

· The grooves between the ribs provide natural channels that allow liquids such as water, oil, and cleaning agents to drain away quickly.

· During cleaning, in pasteurizers, cooling tunnels, or when the product itself contains water/oil, this feature helps keep the surface dry, reduces product contamination, and improves hygiene. It also facilitates air drying.

3. Smooth transition ability

· Inheriting the advantages of plastic modular belts, it can operate flexibly on both horizontal and vertical planes, enabling complex three-dimensional conveying layouts and saving space. The ribbed structure, used with comb plates during transitions, ensures smooth product transfer.

4. Easy to clean and maintain

· The material itself meets food safety requirements (FDA/USDA certified), with a smooth, non-porous surface that does not harbor bacteria.

· Fully detachable, making it easy to thoroughly clean and sanitize individual modules or the entire conveyor. When damaged, only the individual module needs to be replaced, keeping maintenance costs low.

5. High Strength and Durability

· Made of high-performance engineering plastics, it is wear-resistant, corrosion-resistant, and impact-resistant, with a long service life. It can withstand considerable loads and high tensile forces.

In summary, the convex rib belt module is the ultimate solution for preventing slippage, bottle tipping, and transportation difficulties of round items such as bottles and cans during conveying. When used with a comb-type transition plate, the effect is even better, making it an essential component in the modern food, beverage, and packaging industries.