Modular transmission, a new era of intelligent manufacturing

Modular transmission, a new era of intelligent manufacturing – plastic module belts reshape your production line efficiency

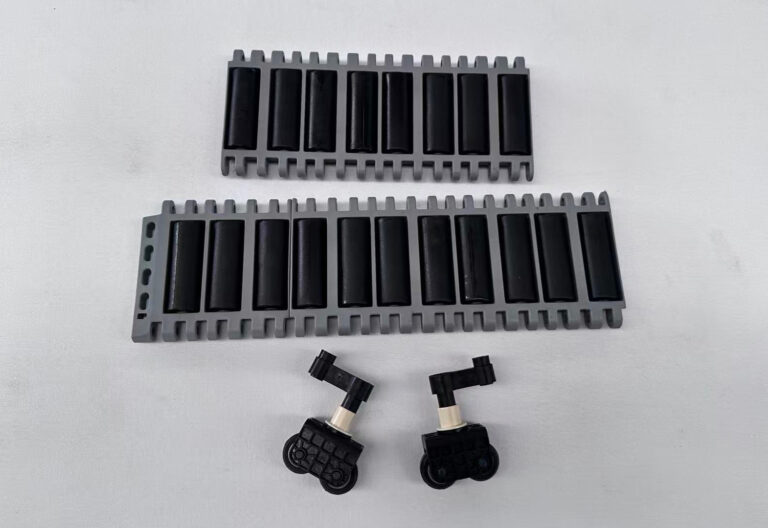

Are traditional conveying methods troubling you in the pursuit of ultimate efficiency and flexibility in modern production? Has the heaviness, rust, high noise, and difficulty in cleaning of metal conveyor belts become a bottleneck for you to increase production capacity and move towards intelligent manufacturing? It’s time to embrace innovation! Donglong’s high-performance plastic module belt, with its excellent design and materials, provides you with smarter, more economical, and more reliable conveying solutions.

Why choose plastic module straps? Disrupting traditional excellence advantages

Extremely lightweight, significant energy saving and consumption reduction: made of high-strength engineering plastics, weighing only 1/4 to 1/5 of a metal strip. Significantly reducing motor load, significantly lowering energy consumption, running more energy-efficient, and directly saving you operating costs.

Excellent corrosion resistance and hygiene: non-toxic, odorless, acid and alkali resistant, corrosion-resistant, fully compliant with strict hygiene and safety standards in the food, pharmaceutical and other industries (such as FDA, USDA certification). The surface is smooth and seamless, does not adsorb materials, and is easy to clean and disinfect, making it an ideal choice for industries such as food processing, packaging, pharmaceuticals, and chemicals.

Smooth and quiet operation, reducing environmental impact: The unique modular structure design and high-precision manufacturing ensure smooth operation and precise positioning. Compared to metal strips, it has extremely low noise, creating a quieter and more comfortable working environment for you.

Ultra long lifespan and easy maintenance: Wear resistant and durable, strong fatigue resistance, and long service life. Adopting modular design, partial damage only requires individual replacement of damaged modules, without the need to stop the line or replace the entire conveyor belt. Maintenance costs are extremely low, and downtime is almost zero.

Flexible design and wide application: It can easily achieve various layouts such as straight lines, turns, climbs, and multiple tracks, perfectly adapting to complex spatial requirements. There are various designs for porosity, which are convenient for process requirements such as drainage, drying, and testing. Widely used in fields such as food baking, fruit sorting, bottle and can transportation, electronic product assembly, packaging logistics, etc.

Empowering industry upgrading, witnessing efficiency revolution

Whether it’s building a new production line or upgrading existing equipment, Donglong’s plastic module strips can be seamlessly integrated, instantly improving your operational efficiency. We offer a variety of materials (such as PP, PE, POM, nylon), various specifications and surface textures of module tapes, and support professional customization services to ensure that they fully match your specific application scenario.

Donglong is not only a supplier of products, but also a trusted partner for you. From scheme design, technical selection to installation guidance and after-sales support, we provide you with one-stop service to ensure you receive the best investment return.

Don’t let outdated conveying equipment limit your imagination. Choose our plastic module straps now, which will become a powerful engine for you to enhance your core competitiveness and drive future growth with lower overall costs, higher operational efficiency, and unparalleled flexibility.

Contact us for free samples and technical consultation, taking a crucial step towards upgrading your production line!